“Never trust a man who leaves his wood plane on its sole,” my father often told me. I grew up covered in wood chips and sanding dust in shipyards during the 1950s. Our medium was wood. We had no power tools—our extension cords were primarily for light bulbs. We were our own source of energy; our bodies, our brawn, our sturdy backs. And our vessels were the direct products of our muscles and, well, perhaps a few brain cells as well.

Take the lowly block plane, as example. We were careful with its blade, especially around used timber. If we hit a nail and nicked the blade, it would take a long time to grind, polish, and sharpen out.

Planes were all about the blade. That’s why we never set a plane on its sole—because continuously setting it on its fragile, thin cutting edge soon dulled it. And, of course, increased the chances of the blade getting nicked.

And, yes, nomenclature was important. Planes had soles, not bottoms or downsides. We knew that if we wanted to do precise work, we needed to have precise words to nurture it.

Sharpening the blade of a block plane was an art for two reasons. First, the blade had to be sharpened at the precise angle it was machined so it would be parallel with the sole. Second, it couldn’t be sharpened with a circular motion because that would, eventually, slightly round-the blade—making it more difficult to plane a truly flat surface.

Silly? These tools-with-blades weren’t throw-aways. I still have planes I used with my father on the schooner Elizabeth (mid-1950s) and chisels my father used on the sloop Dorothy (late-1920s), nearly a hundred years ago.

We were so protective of our plane blades back in the day, that we carried in our toolbox a second plane with a damaged blade in case we had to plane some used timber that might have a hidden fastening lurking within.

Up until now, we’ve only mentioned small block planes—but there were also bench planes, jack planes, jointer planes, and more. Molding planes, intended to make multi-surfaced trim pieces often had numerous blades.

Want to shape your round spar? Then a compass plane with a curved blade (oh, what a bitch to sharpen!) was just the thing.

Bullnose planes could be finely adjusted and were great for delicate trim work. Rabid Filister planes had adjustable fences. If you wanted to prepare the edges of some Sitka Spruce for a glued box mast, a jointer plane was just the thing. And we haven’t even mentioned dovetail, router, chisel, or plow planes. Bench planes were called that because every shipwright had one on his work bench, within easy reach.

Even the lowly block plane came in two versions—a 20-degree angle blade for general application, a 12-degree blade for hardwoods like teak.

And some wood butchers (an affectionate name for a master carpenter) scoffed at metal. They had a whole tool chest of wooden-bodied planes with metal blades, but wood bodies. These were said to be ‘kinder to the surface’ and ‘less sticky.’

Yes, the soles of planes were sometimes waxed, especially if you were planning sappy, just-cut timber.

The wood itself was of utmost importance—the elm you’d steam for a deck beam was different than the oak you’d steam for a frame. (Boats don’t have ribs—and you’d be tossed out of a shipyard for such blasphemy.)

Mahogany was just soft and stable enough for planking—but not too soft, like the spruce that was perfect for spars.

Other considerations were: strength and rot resistance. Did the wood split at the fastenings? Did it warp? Could it hold paint? If the vessel was headed for the tropics, how did it stand up to teredo worms? Or, even worse, in some waters were the boring gribbles? (Great name for a marine rock group: the Boring Gribbles!)

For example: teak is wonderful because of its sturdy oils—which, alas, makes it a poor wood for laminating.

Everything on a boat is a compromise.

And we haven’t even talked about chisels. I still carry over a dozen on Ganesh—which is about half the number of different types in regular use when I was a child. Nowadays buyers at Walmart are usually limited to the flat chisel—good luck finding a firmer, mortise, paring, or construction chisel.

Yes, of course, paring chisels were used to gently pare joints. (Sounds quaint, doesn’t it?)

Beyond the Reef: Sunken Planes & Pirate Ship Newest BVI Dive Sites

And we haven’t gotten to a cold chisel yet—those were usually used on metal.

Shapes of chisels were important: flat, cross cut, side cut, round nose, diamond point, and cow mouth were common.

A close cousin to the chisel to a 1950s shipwright was a caulking iron.

Both chisels and caulking irons weren’t hit by hammers but rather hardwood mallets. These came in different varieties and weights. For carving, I used a large, round wooden shape—if made of Lignum Vitae, all the better. Rubber tipped hammers and bumping hammers were okay for chiseling, if the head was big enough.

Caulking mallets and irons were a ‘hole ‘nother story. I was taught to caulk seams by professionals at Rentner’s Boat Yard, every one of which had a large portable wooden bin with a long bar handle that he’d carry up onto the scaffolding with him while caulking. Inside were dozens of irons and at least six mallets.

Each seam varied in width. You caulked by sound, not sight and the wider the seam, the shorter the ‘tucks’ or ‘nips’ of cotton were. You didn’t fill the entire seam with cotton. You made the cotton into a tight ball towards the rear of the seam and used Woolsey’s seam compound to flush it out. (I still smell that seam compound in my dreams!)

That’s right—strands of cotton caulking were never laid upon each other. A single strand of cotton was used and the trick was getting the ‘packing’ tight yet not blowing out the inside edge of the seam.

If done right, the wood would squeeze around the cotton. When you removed a well-caulked plank, you’d be able to clearly see the round indentation of the cotton in the plank edges.

Caulking is nearly a lost art now in the West. Luckily, I can occasionally still hear the sound of mallets from Malaysia, where wooden boat building still thrives.

There’s a problem with wood—it is milled straight and flat but nothing on a boat is. I’ve Spanish-windlassed (wound two strands of wire with an inserted stick) my planks onto my frames. However, in the area where the garboard meets the horn timber, not only must the planks bend in, they must also twist.

Luckily, most shipyards in the 1950s had an old discarded metal/porcelain bathtub hanging around just for this purpose. We’d haul it near our vessel, fill it with water, then build a raging fire underneath. Next, we jammed heating ducts just above the water—and cover the whole mess with a tarpaulin, careful not to allow the tarred canvas to ignite.

Complicated? Difficult? Time-consuming?

You bet!

Then we’d slip our planks into those heating ducts and ‘cook’ them for just the right amount of time. Then we’d snatch them out and bend/twist them into place before they cooled.

Looking for a Good Cruising Sail? Tips and Guidelines for Dacron

On Corina, my 1932 Atkins double-ender, I steam-bent all my deck beams using a heavily constructed frame that was two inches greater than the crown of my deck. Once off the frame, the beams relaxed into the perfect crown. (Deck crowns are a whole different subject—just be aware that they are not a fair curve, even to this day.)

All this stuff wasn’t easy. It was fun to learn in the abstract but difficult to master in the practical. In fact, paying the deadwood seam on a wooden carvel vessel was so extremely difficult that the seam became widely known as the Devil.

This is where we get the saying, “…the devil to pay!”

And if a sailor falls overboard and starts drowning, he might be saved if still splashing on the surface—but he’s a goner if he’s ‘…between the Devil and the deep blue sea.”

I could, of course, go on and on. Drawspokes, anyone? Do you know how to swing an adze? Both were common in my day—as was splicing your own rigging wire, arming your own sounding lead with wax, and rocking the lower limb of the sun in your sextant mirror.

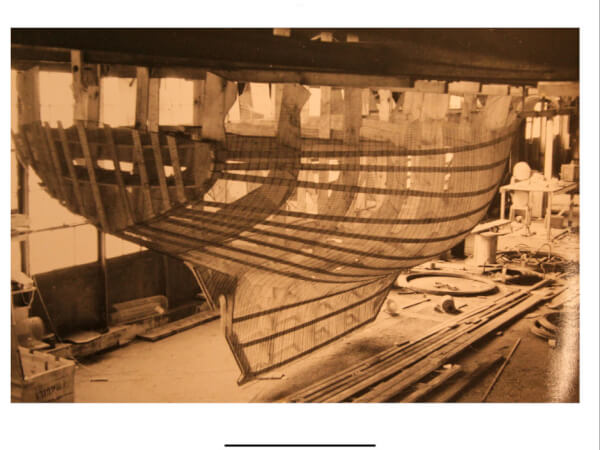

But if you added all of the skills above together, you could take on the second biggest challenge—to build a vessel from scratch.

I’ll never forget in 1971, after sending in my $25, unrolling the blueprints of a ferrocement Endurance 35 ketch, designed by Peter Ibold. Here were a dozen pieces of thin paper—and all my hopes and dreams within. Just paper. Nothing else. Just paper, mixed with dreams and irrigated with sweet sweat and grim determination. Three years later, we splashed. Three years after that, we sailed Carlotta across an ocean.

There’s nothing like that feeling. The poet John Masefield expressed boatbuilding best, “…built out of chaos, brought to law!”

If the Good Lord had taken me as I luffed up into Long Bay on St. Thomas, I’d have died a happy, fulfilled man.

So, dear reader, allow me the occasional secret smile of an old man.

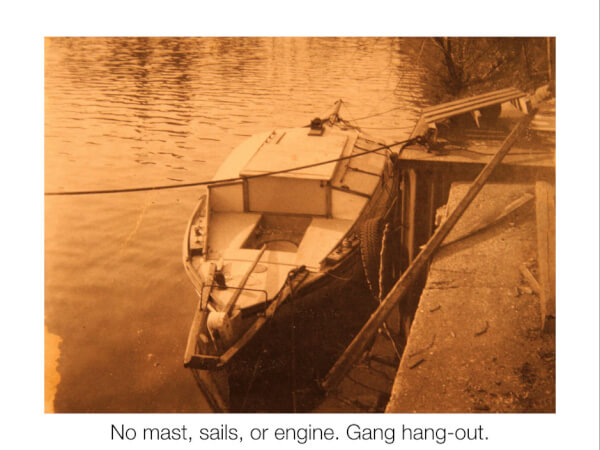

Yesterday while dock strolling, I met an earnest young fella standing in the companionway of a Westsail 32. The Westsail is an extremely seaworthy design. Eight hundred and thirty were built during the ‘70s—from a discarded mold purchased cheap from the defunct Kendall Boat Corporation.

“Nice boat,” I said, being a great admirer of both William Atkins and Colin Archer.

“Thanks,” he said.

I started to move on but stopped when he said, “I built her.”

I wanted to keep going but could not.

“Really?” I said, and resisted the temptation to ask if he’d built her in the womb.

“Well, the original bare hull was built in California,” he said, “and a previous owner slapped together the interior—but when we got the ole gal she was a total mess! She needed new curtains, new chart plotter, new Bimini—hell, we even had to replace the refrigeration system!”

I looked at him. And nodded.

“Good on ya,” I said as I sauntered away, “Good on ya!”

Editor’s note: Cap’n Fatty has penned many books about cruising—ten of which are still in print.